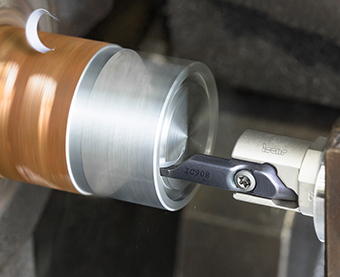

IC806应用于市场需求颇高的ISO车刀片及车削切槽刀片(霸王刀片),现将IC806牌号推广至平装螺纹加工车刀片,用于航空工业美制标准UNJ螺纹的外圆及内孔加工,加工诸如Inconel 718这类高温合金。

ISO and IC806 used in turning the car blade market demand high cutting blade (blade, King) will now be extended to a IC806 grade thread processing car blade, used for cylindrical hole processing in aviation industry of American Standard UNJ thread processing, such as Inconel 718 this kind of high temperature alloy.

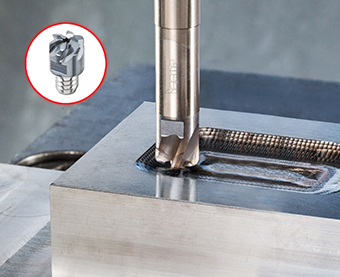

MINCUT系列新刀片MIFR 15及其刀杆,用于实现最大切削深度达15mm的端面切槽及车削加工,还可用于深孔的切槽加工及旋转加工。

MINCUT series new blade MIFR 15 and its cutter bar are used for cutting and turning end face with maximum cutting depth of 15mm. It can also be used for cutting groove and rotating machining of deep hole.

新MIFR 15刀片采用螺钉夹紧方式高刚性夹持于MIFHR15刀杆的长定位槽中,能实现高的切削参数,且收获更长的刀具寿命。刀片合金牌号为IC908。

The new MIFR 15 blade adopts a screw clamping method, and the high rigidity is clamped in the long locating slot of the MIFHR15 cutter rod, and the high cutting parameter can be achieved, and a longer tool life can be obtained. The blade alloy is IC908

MM EFF铣刀头因其大圆弧顶面切削刃结构设计而能实现更高的进给。独特的切削刃形状使得切削合力轴向指向主轴。即便在大悬伸下也能以大进给加工,并收获高的加工稳定性。MM EFF铣刀头可在0.3-0.7mm切削深度下实现每齿最大进给0.5mm,显著缩短了加工周期;其独特的大圆弧切削刃使得在槽铣、型腔铣、螺旋插补铣或最大切削深度达3XD的等高轮廓铣中收获高生产率。

MM EFF milling head can achieve higher feed because of its large arc top cutting edge structure design. The unique cutting edge shape causes the cutting force to point axially to the spindle. Even under large overhang, it can be processed with large feed and harvested with high machining stability. MM EFF cutter head can achieve maximum feed per tooth cutting depth in 0.5mm 0.3-0.7mm, significantly shorten the processing cycle; its unique arc cutting edge makes the high contour milling and groove milling, cavity milling, spiral interpolation milling or maximum cutting depth of 3XD in the harvest of high productivity.

【此文章原创来自于158机床网转载请注明出处】

.