电机壳的加工策略主要依据:

- Design (with / without water coolant jacket) 设计(是否带水冷套)

- Volumes (lathes / machining centres) 产能 (车削 / 加工中心)

Low volumes:

vertical lathe (+ machining center) 小批量采用立车(+加工中心)

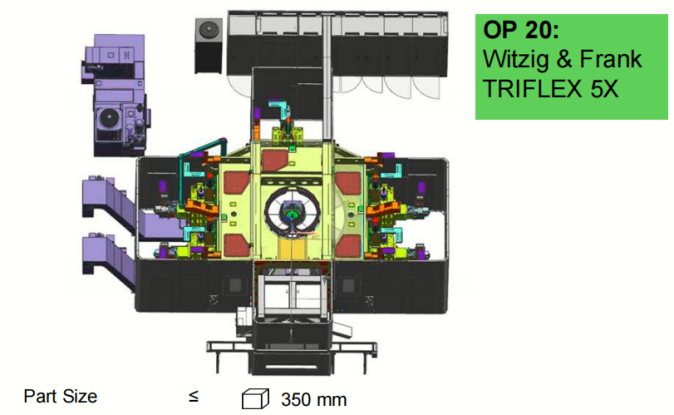

Medium volumes: vertical lathe + TRIFLEX 5x machining center 中等批量 采用立车 + Triflext 5x加工中心

High volumens: TRIFLEX 5X + TURMAT

大批量 采用 Triflex 5x + Turmat

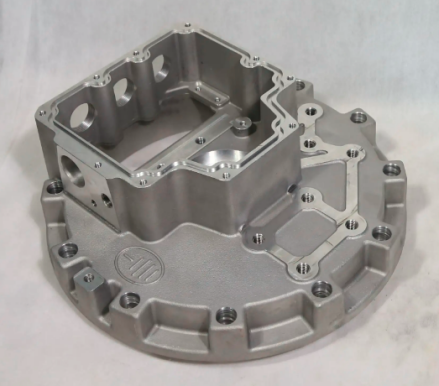

混合电机定子外壳参考:

Machining in two (2) Operation. 两个工序:

• OP 10 by Turning machine 车削

• OP 20 by Milling machine type TRIFLEX 5X Triflex 5x 铣削

Machining process: 加工工艺

• OP 10:

Pre / Finish turning outside and inside contour (Ø > 200mm) 预、精车外侧和内侧轮廓(Ø > 200mm)

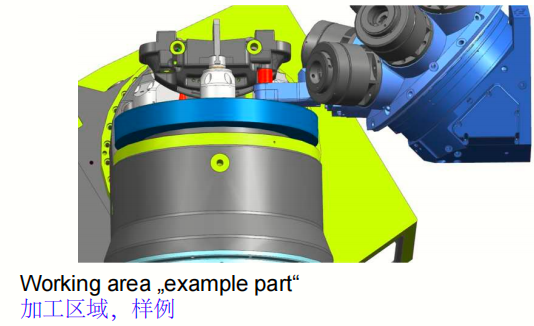

• OP 20:

Drilling and milling content 钻、铣

Finish ream inside Ø > 200mm 精铰内侧 Ø > 200mm)

咨询电话:135 2207 9385

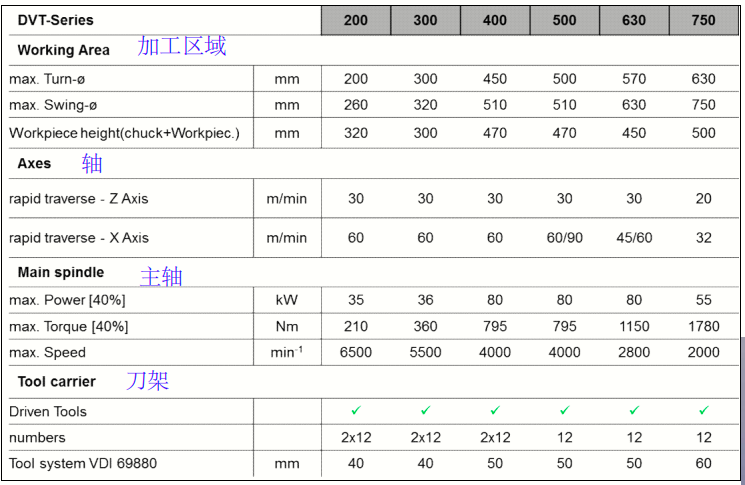

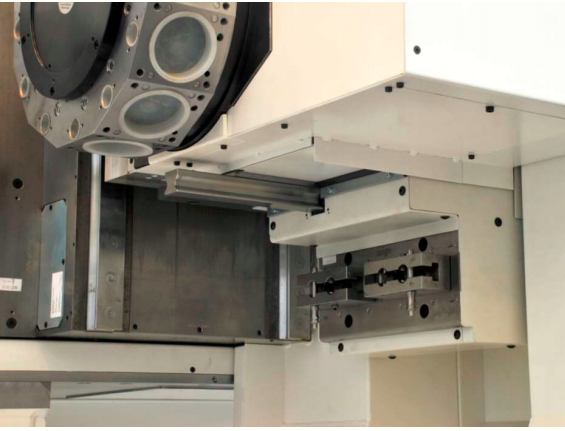

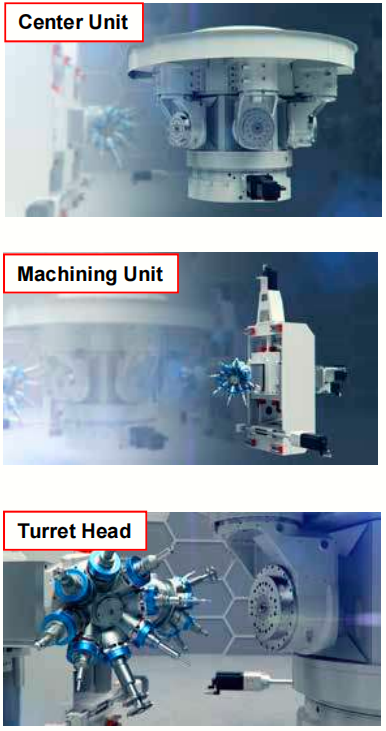

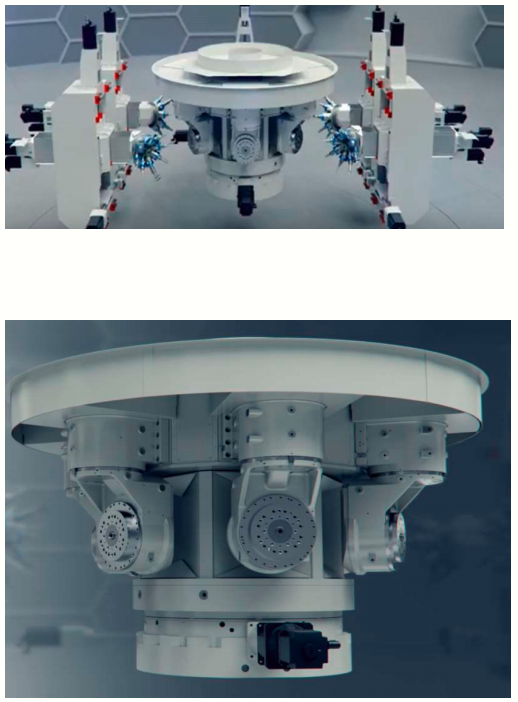

Working Area DVT 400

加工区域

• Six (6) stations 6工位

• Turret heads 刀塔头

• 5 axis machine 5轴

• Standard machine 标准机

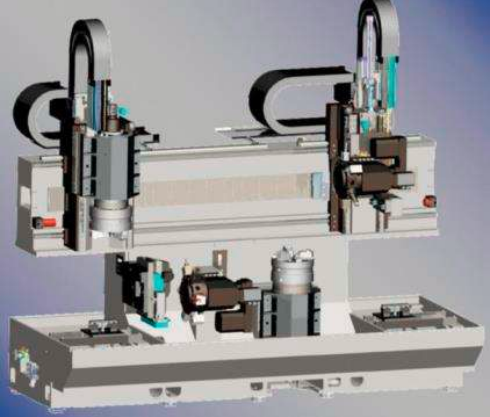

Machine Concept Design 加工概念

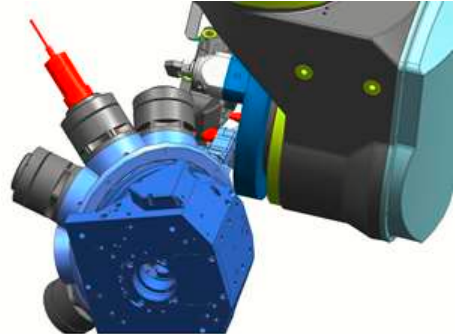

§ Simultanous 5-Axis Machining with five (5) single spindle 五轴联动加工

Parallel 5-Side Machining in one clamping / one set-up 一次装夹五面加工

Load- and unlaoding during machining 加工过程中上下料

High Flexibility and Productivity 高柔性、高效率

产品亮点:

˃ Simultaneous 5 – Axis Machining with five (5) spindles

五轴联动加工

˃ Load - / Unloading of parts and fixtures during machining

加工中同步上下料

˃ Highest availability (no motor spindle, no tool changer )

最大可行性(无电机主轴、无换刀)

˃ Free chipfall direct in chip conveyor, dry / MQL machining

排屑器,干式,MQL加工

˃ Compact design with short axis movements (box in box)

紧凑型设计带最小轴移动

˃ Fastest tool change > Chip – to Chip < 1.9 s

快速换刀 屑-屑小于1.9s

˃ Easy programming, operating and quick part change over

易于编程,操作,更换零部件

˃ Standardized modular 6-Station Rotary Transfer Machine

标准化模块,6工位转台式

˃ Each station with tool change – 8 spindle index turret head

每个工位都带换刀,8主轴分度刀塔

˃ Full integratetd standardized flexible automation system

集成式标准化柔性自动系统

˃ Quick change over and set-up with zero clamping fixtures

快速转换、零点装夹

˃ Simultaneous OP 10 & OP 20 machining in one (1) set- up

一次装夹同时完成OP10和OP20

˃ Full flexible 5- Axis Machining with five (5) single spindles

五个独立主轴,柔性化加工

˃ Easy programming, operating and quick part change over

易于编程,操作,更换零部件

Highest Quality

˃ Full compensated single spindle machining 单轴加工全补偿

˃ Optional temperature compensation 可选温度补偿

˃ Clear tracking of quality characteristics 质量监控

˃ All axis with absolute direct measuring system 绝对测量系统

˃ Rigid design with box in box units and closed frame 刚性设计

Less cost per part

˃ Highest availability ( +6% ) 最高可用性

˃ High productivity on small footprint ( -30% ) 占地小,产能大

˃ Lowest technology cost ( -80% - tool and fixtures ) 最低技术成本

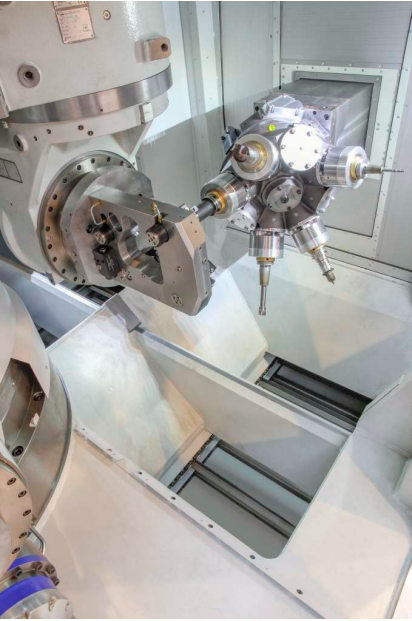

柔性化五轴加工中心完成OP10, 装夹在粗加工完成; 预加工可在一次或两次操作中完成。

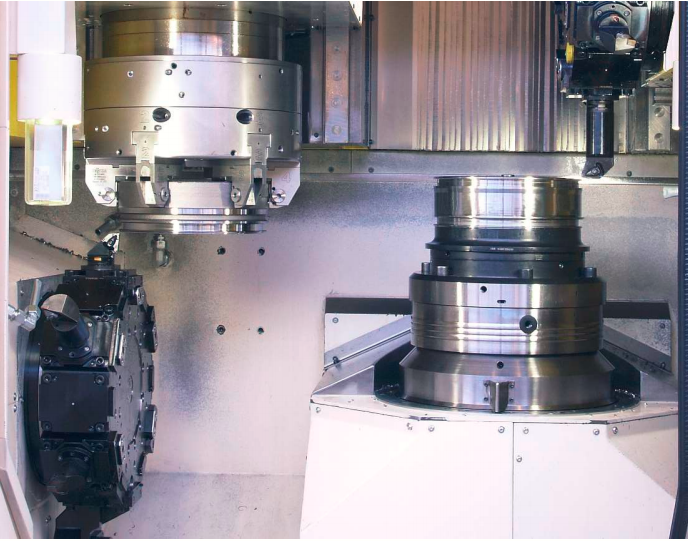

电机壳关键部分的精加工在TURMAT机器上进行。TURMAT机器专门为此类部件设计,通过立式定子轴加工。

轴承支架加工概念

Triflex 5X一次装夹完整加工