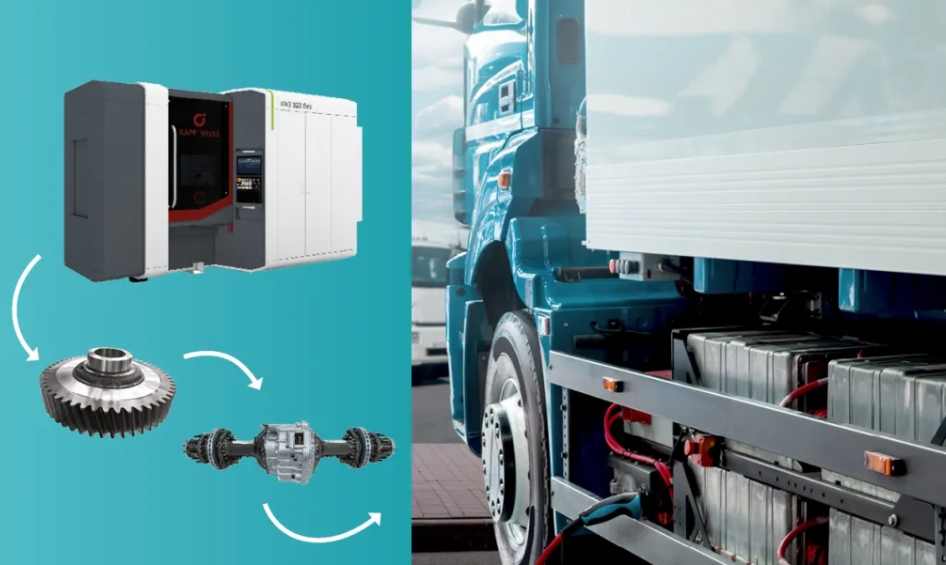

E-mobility has brought about various application areas with new challenges for gear manufacturing. From miniature gears in bicycle drives to the gears installed in cars and even larger workpieces in trucks - KAPP NILES machines offer the flexibility to meet a wide range of requirements.

电车为齿轮制造业带来了各种各样的应用领域,同时,全新的挑战也应运而生。从自行车的微型齿轮到汽车的内置齿轮,甚至是卡车的大型工件,KAPP NILES 的机床都能灵活地满足各种要求。

1、E-Bike电动自行车

Gears for bicycle drives are both very small and difficult to machine due to demanding workpiece geometries. Nevertheless, solutions are needed to manufacture these components in an equally productive, economical and consistent quality manner. All previously known fine machining processes have reached their limits here.

由于工件几何形状需要精益求精,因此用于自行车驱动的齿轮不但体积小,而且难加工。但我们仍需迎难而上,以高效的、经济的、质量稳定的方式来加工这些部件。所有之前已知的精细加工工艺至此都已达极限。

Only through the development of generating grinding with the smallest tools is there a process that meets all requirements. Find out how you can use it to machine even complex gears precisely and efficiently in our expert article ‘Small worm - great potential’.

对此,只有通过开发使用小直径蜗杆砂轮刀具展成磨削工艺,才能满足所有要求。如需了解如何使用它精确高效地加工复杂的齿轮,敬请参阅我们的专家文章《小蜗杆—大潜力》。

2、E-Car电动汽车

The majority of electric cars use simple, non-shiftable transmissions consisting of input shaft, intermediate gear, intermediate shaft and differential gear. The requirements for these gears are very high due to the extremely wide speed and torque range. KAPP NILES offers the answer for reliable machining of these workpieces with highest quality.

大多数电动汽车使用由输入轴、中间齿轮、中间轴和差动齿轮组成的简单、不可换挡的变速器。由于速度范围和扭矩范围宽泛,因此对这些齿轮的要求极高。KAPP NILES 可以为这些工件的可靠加工提供最高质量的解决方案。

Find out how KAPP NILES supported the development of a new drivetrain for a fully electric sports car in our success story ‘Transmission for e-sports cars’.

如需了解KAPP NILES 如何为一款纯电跑车的新型传动系统的开发提供支持,敬请参阅我们的成功案例 “电动超跑变速器”。

3、E-Truck电动卡车

咨询电话:13522079385

The demands on the quality of gears have also increased in leaps and bounds for electrically driven commercial vehicles. Higher torques must be transmitted with high efficiency over a wide load range. At the same time, durability plays an important role. We have advanced our grinding and measuring machines as well as their machining processes and chains accordingly.

电动商用车对齿轮质量的要求也在突飞猛进。更高的扭矩必须在宽负载范围内以高效率传输。与此同时,耐用性也发挥着重要作用。为此,我们已经相应地改进了我们的磨齿机和测量仪及其加工工艺和链条。

Find out what challenges KAPP NILES has overcome in grinding large components for e-trucks in our success story ‘Electric truck: Polished gears in XXL’.

如需了解KAPP NILES 在磨削电动卡车大型部件过程中克服了哪些挑战,敬请参阅我们的成功案例 “电动卡车XXL抛光磨齿轮”。