Rapid X = 50 m/min, rapid Y = 60 m/min,

rapid Z = 60 m/min

温度补偿功能

温度补偿是用来控制X,Y,X2和Z轴方向上由于温度变化引起的尺寸差异。

温度补偿系统基于两个测针:

一个测针用于测量机床支架(=环境温度)以便补偿铁质支架的膨胀。这个测针固定于机床支架上

.第二个与电线相连接的测针用于测试铝型材的温度来做补偿

25KW主轴性能特征:

20 kW (S1), 25 kW (S6) -22.000 RPM –HSK-A63 tool holders. 主轴功率、转速、刀柄规格

The spindle is water cooled with an airco system.

CNC rotation of the spindle (A-axis) between -110°and +110°-rapid = 300°/sec A轴旋转角度

CNC rotation of the fork (C-axis) between -225°and +225°-rapid = 300°/sec C轴旋转角度

Maximum tool length 220 mm -longer tools possible with manual tool change 最大刀长

Maximum tool diameter is 700 mm 最大刀具直径

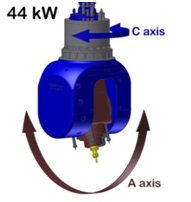

44KW主轴性能特征:

39 kW (S1), 44 kW (S6) -24.000 RPM –HSK-A63 tool holders. 主轴功率,转速,刀柄规格

The spindle is water cooled 水冷式主轴

CNC rotation of the spindle (A-axis) between -110°and +110°-rapid = 300°/sec A轴旋转角度

CNC rotation of the fork (C-axis) between -225°and +225°-rapid = 300°/sec C轴旋转角度

Maximum tool length 220 mm -longer tools possible with manual tool change最大刀长

Maximum tool diameter is 700 mm最大刀具直径

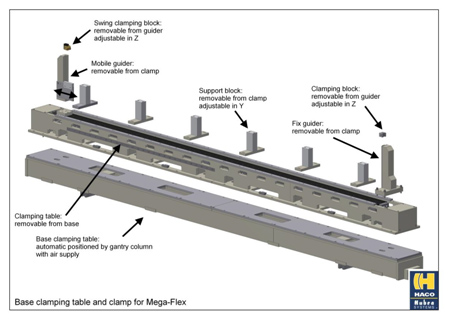

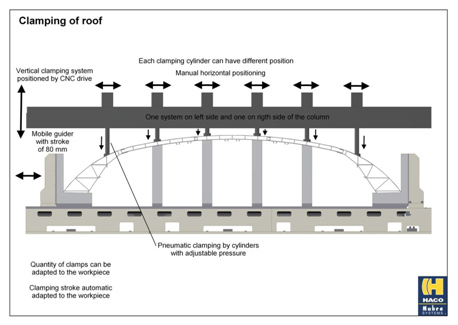

夹具系统

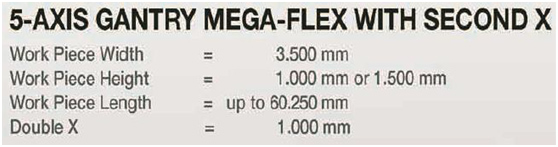

夹具系统-火车地板

夹具系统-车顶

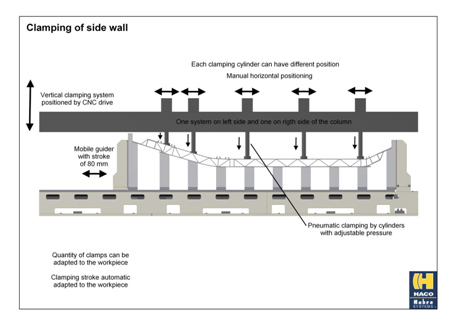

夹具系统-侧墙

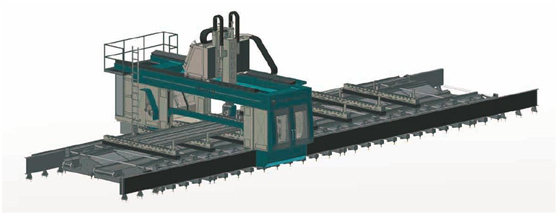

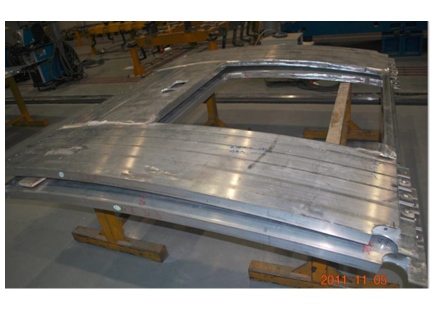

哈科该型号型材加工中心应用实图

咨询135-2207-9385。