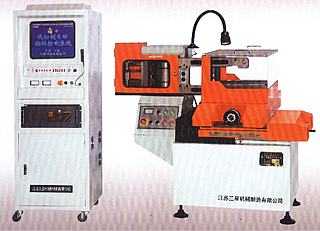

。 机床走丝配有专利“电火花线切割机床电极丝双向张紧机构”;。 多次切割参数(高频参数、走丝速度)一次设定,智能控制;。 试件加工精度:正负0.005mm;。 最佳表面粗糙度:Ra≤1.2um;。 最大加工速度:160mm2/min;。 三次切割的平均速度达80mm2/min左右(一割二修,表面粗糙度≤1.5um) 。 系统采用绘图式自动编程软件,同时兼容autoCAD图形文件;。 整机电柜集编程、控制、高频电源、机床电器一体化立式控制柜, 电脑采用工控机,15”液晶显示屏,操作方便;。 机床采用无触点感应式換向开关,走丝速度变频调速;。 适用于精密零件和模具的加工。 Features of{he Wire Cuttinq EDM Thc nmchine iS cndowcd With Wil.e tightening system”.patent for its wire running systein. Pal.ametei.of multi—cutting(parameter ot high frequency,wire running speed)once fixed,the machine can be intelligently controlled The Processing accuracy:±O.005mm .Fhe best SUI.face roughncss:Ra≤I 2 Ll m The ii]ax cutting speed:1 60ram’/min 7he avel‘age speed of triple cuttiug is about 80mm’/min(one cut。anothel two CUtS for mortitication for raising accuracy and reducing sI.n.face roughness 01.workpiccc,surface roughness≤1 5 u m) 7he system adopts the cal.tography type automatic progralnnfing software,autoCAD g1.aphic file is compatible simultaneously The overall clcctricity controller is a vertical control box integ~.ating in function of programming,control,high frequency,power electric pal.tS The computer iS the pl‘ofcssional COmputer for industria]use with 15“ 1iquid CI.ystal SCl eeu enabled the machine to bc easy for open This machine applies Non touch point induction type direction switch.The wire running speed can be adjusled through frequency conversion The machine iS suitable for processing mold and the components high in precision.机床型号 Type DK7720E DK7725E DK7732E DK7740E DK7750E 工作台面尺寸(mm) Worktable size 450×318 520×336 576×336 720×460 846×555 工作台行程(mm) Table travel 200×250 250×320 320×400 400×500 500×630 加工工件最大厚度(mm) Max.workpiece thickness 100 100 100 160 200 试件加工精度(mm) Workpiece accuracy ±0.005 ±0.005 ±0.005 ±0.005 ±0.005 最佳表面粗糙度Ra(цm) Best surface roughness ≤1.2 ≤1.2 ≤1.2 ≤1.2 ≤1.2 最大切割速度(mm2/min) Max.cutting speed 160 160 160 160 160 机床总功率(KVA) Overall power ≤1.6 ≤1.6 ≤1.6 ≤1.6 ≤1.6 工作液 Cutting liquild多次切割专用乳化液 Special fluid for multi-cutting