与普通光源相比,激光具备高亮度、高方向性等优异特性,已经成为一种新的技术和手段,广泛应用到通信、工业加工、军事武器、医疗等诸多领域。

Compared with ordinary light, laser has excellent properties such as high brightness, high directivity, and has become a kind of new technology and method, widely used in communications, industrial processing, military weapons, medical, and many other fields.

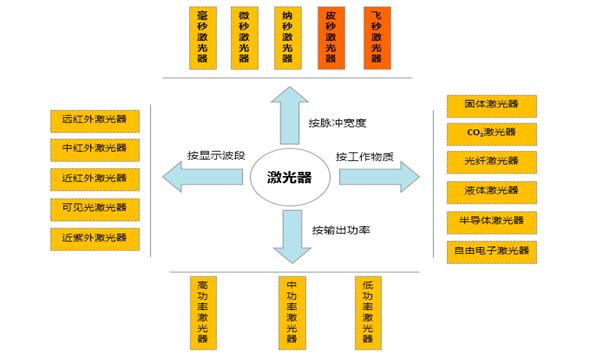

激光器是产生、输出激光的装置,按照激光工作物质类别的不同,可将激光器分为气体激光器、液体激光器、固体激光器、半导体激光器等;按照波长的不同,一般可以将分为红外激光器、可见光激光器和紫外激光器;按照脉冲宽度的不同,可分为毫秒激光器(10-3秒)、微秒激光器(10-6秒)、纳秒激光器(10-9秒)、皮秒激光器(10-12秒)、飞秒激光器(10-15秒);按照输出功率的不同,可分为高功率激光器(1000W以上)、中功率激光器(100W-1000W)、低功率激光器(100W以下)等。

Laser is generated, the output of the laser device, according to the type of the laser work material is different, the laser can be divided into gas laser, liquid laser, solid laser, semiconductor laser, etc.; According to the different wavelength, it can be divided into infrared laser, visible laser and ultraviolet laser. In accordance with the pulse width is different, can be divided into millisecond laser (10-3 seconds), millisecond laser (10 to 6 seconds), nanosecond laser (10 to 9 seconds), picosecond laser (10-12 seconds), femtosecond lasers (10 to 15 seconds); According to the different output power, it can be divided into high power laser (over 1000W), medium power laser (100w-1000w), low-power laser (below 100W), etc.

以皮秒与飞秒激光器为代表的超快激光器具有极短的激光脉冲(脉冲持续时间只有几个皮秒或飞秒)和极高的峰值功率的特点,用于材料加工具有独特的超精细、无热影响等优异性能。

Represented by picosecond and femtosecond laser ultrafast laser has a very short laser pulse (only a few picosecond and femtosecond pulse duration) and the characteristics of high peak power, used for processing materials, has a unique ultra-fine, no heat affected such as the excellent performance.

Processing "hyperfine" - ultrafast laser can focus to ultrafine space area, at the same time has a very high peak power and a short laser pulse, when processing section and tidy, thermal diffusion, micro cracks and metallurgical defects, processing process will not affect the space around the range of materials involved, to do the hyperfine processing.

加工的“超精细”--超快激光能够聚焦到超细微空间区域,同时具有极高峰值功率和极短的激光脉冲,加工时切面整齐、无热扩散、无微裂纹及冶金缺陷,加工过程中不会对所涉及的空间范围的周围材料造成影响,从而做到了加工的超精细。

The thermal process will play a major role in the processing of the "no thermal impact" -- the traditional laser with the pulse duration greater than 10ps and the effect of the material. Pulse duration less than 10 ps ultrafast laser, because only picosecond and femtosecond pulse duration magnitude, is far less than the material in the excited electron transfer by energy release in the form of time, energy to release the pulse has ended, and avoid the energy transfer, transformation and the existence of the heat and thermal diffusion, to realize the true sense of the word "cold" laser processing.

加工的“无热影响”--脉冲持续时间大于10ps的传统激光,与材料作用时,热过程将起到主要作用。脉冲持续时间小于10ps的超快激光,由于脉冲持续时间只有皮秒、飞秒量级,远小于材料中受激电子通过转移转化等形式的能量释放时间,能量来不及释放该脉冲已经结束,避免了能量的转移,转化以及热量的存在和热扩散,实现了真正意义上的激光“冷”加工。

Ultrafast laser has a very wide range of industrial applications, with new shows, biological, medical, consumer electronics, 3 d printing, high-end equipment, such as the development of new applications, for laser machining precision demand is higher and higher, ultrafast laser has become an important direction of precision machining. Laser enterprises at home and abroad have laid out the laser/ultra fast laser equipment market. In the core ultra-fast laser market, it is currently dominated by foreign companies, which are represented by the company, such as coherent, spectral physics, fast, NKT, EKSPLA,

超快激光的工业应用非常广泛,随着消费电子、新型显示、生物医疗、3D打印、高端装备等新应用的发展,对于激光加工精细度要求越来越高,超快激光已经成为精密加工的重要方向。国内外激光企业纷纷布局激光器/超快激光设备市场。在核心超快激光器市场,目前基本上是外国公司占主导,以相干,光谱物理、通快、NKT、EKSPLA、Lihgt Conwersion、lumentum、EdgeWave、AMPlitude等公司为代表。大族激光、华日激光、安扬激光、虹拓新科技、盛雄激光、贝林激光、卓镭激光等国内企业正大力推进技术产业化,在超快激光设备、激光精密加工、激光器技术的研发、技术应用和产品生产等产业环节取得快速发展。

Conwersion, lumentum, EdgeWave, etc. Ethnic group, China laser, AnYang laser, extension of new technology, ChengXiong laser rainbow, behring, zhuo laser laser and other domestic enterprises are vigorously promoting technology industrialization, the ultrafast laser equipment, laser precision machining, laser technology research and development, technology application and product production industries such as link achieved rapid development.

【此文章原创来自于158机床网转载请注明出处】