如果说制造业是国家的基础和命脉,那机床则是制造业的重中之重。没有机床,就没有电掣风驰的高铁;没有机床,就没有鹰击长空的战斗机;没有机床,就没有飘洋远行的航母。

If manufacturing is the foundation and lifeblood of the state, the machine tool is the top priority in manufacturing. Without machine tools, there is no high-speed rail. Without the machine tool, there would be no eagles flying fighter; Without machine tools, there would be no flying carriers.

但是一直以来,我国的机床产业都走着一条极为艰难的道路。

But the machine tool industry in our country has been taking a very difficult road.

我国的工业起步晚、技术落后,而且几乎是在一穷二白的境况之下开始的,机床也在其中。

1958年,在苏联的援助之下,我国研制出了第一台数控机床,从此开始数控机床的发展之路。到了六十年代,欧美对中国进行技术封锁,苏联也停止对中国的援助,机床行业依靠着自立更生发展出十八家骨干企业,也就是后来的机床行业“十八罗汉”。

In 1958, with the aid of the Soviet union, China developed the first CNC machine tool and began the development of CNC machine tools. In the 60 s, Europe and the United States to China technology blockade, the Soviet union also stop aid to China, rely on the machine tool industry develop self-reliance 18 backbone enterprises, which became "18 arhats" machine tool industry.

These 18 enterprises quietly supported the development of the whole equipment manufacturing industry and industry in China at that time. By the end of 1965, these enterprises had accumulated 26 kinds of high-precision precision machine tools.

这十八家企业默默支撑着我国当时整个装备制造业乃至工业的发展,到1965年底,这些企业累计掌握的高精度精密机床品种达26种。

到了改革开放以后,先进的技术和机床流入中国,受外来技术的冲击,原本落后的机床技术已经不能满足生产需要。十八家企业经历了破产、兼并、重组,外资企业在中国建厂,民营机床企业也正式进入市场。

After the reform and opening up, the advanced technology and machine tools flowed into China, which was affected by the foreign technology, and the outdated machine tool technology could not meet the production needs. Eighteen enterprises have experienced bankruptcy, merger and reorganization, and foreign enterprises have established factories in China, and private machine tool enterprises have entered the market.

事实上,虽然这些机床产业发达的国家在中国赚的捧满钵满,但是真正的核心技术却一直禁止出口到中国。比如用于加工哈勃太空望远镜镜面的超精密机床,1990年已经制造出来,而这种机床对于加工航空发动机叶面卓卓有余,然而20年后的今天,中国企业还在苦苦探索。

再比如控制器,控制器是数控机床的核心,相当于电脑的CPU,是制造数控机床的关键技术。然而目前,以日本FANUC和德国SIEMENS为首的控制器巨头的产品垄断市场80%以上,高端产品不仅垄断,而且限制中国进口。日本人称“没有日本的机床,中国的汽车产业将寸步难行。中国对日本的依赖只会越来越加强而不会越来越削弱。这就意味着“日本越来越有能力控制中国”。这些话虽然有些狂妄,但中国在工业产生领域的弱项却是事实。

These countries still have some old routines, in China also produce five-axis machine tools, only sell three axis machine tools in China, when China developed five-axis machine tools, their five-axis machine tools immediately dumping in China. In this way, the high-end machine tool technology is not allowed to enter China, which hinders the development of Chinese machine tool enterprises.

这些国家还有一些惯用套路,在中国还生产不出五轴机床的时候,只在中国卖三轴机床,当中国研发出五轴机床的时候,他们的五轴机床立刻在中国倾销。这样一来既禁止了高端机床技术进入中国,又阻碍了中国机床企业的发展。

If manufacturing is the foundation and lifeblood of the state, the machine tool is the top priority in manufacturing. Without machine tools, there is no high-speed rail. Without the machine tool, there would be no eagles flying fighter; Without machine tools, there would be no flying carriers.

可以说,中国机床企业一直在夹缝中生存。不仅高端机床和技术被限制进口,而且市场也在被外来企业不断蚕食中。

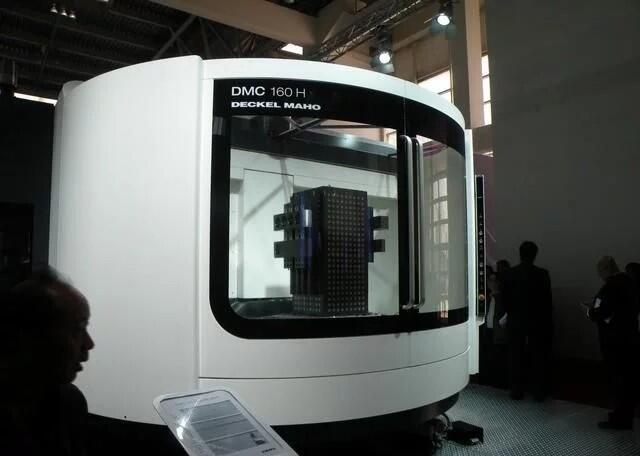

中国的高端机床市场,一直被日本的FANUC、MAZAK、大隈、牧野,德国的DMG、哈默,美国的哈斯这样的国际一线机械生产企业凭借着顶级的技术和一流的品质牢牢把控;而在中低端市场,台湾地区的丽驰、友嘉、东台、台中精机等又成为大陆企业最强的对手。

It can be said that Chinese machine tool enterprises have been living in the cracks. Not only are high-end machine tools and technology restricted to imports, but the market is also being eroded by foreign companies.

【此文章原创来自于158机床网转载请注明出处】